[ad_1]

When the new owner rides the Pedego electric bike for the first time, it has traveled thousands of miles in the global supply chain affected by the epidemic.

The California company’s most affordable model, the Element, is manufactured in Shanghai and shipped to US ports Los Angeles-Long Beach, And then trucked to nearly 200 dealers across the United States.

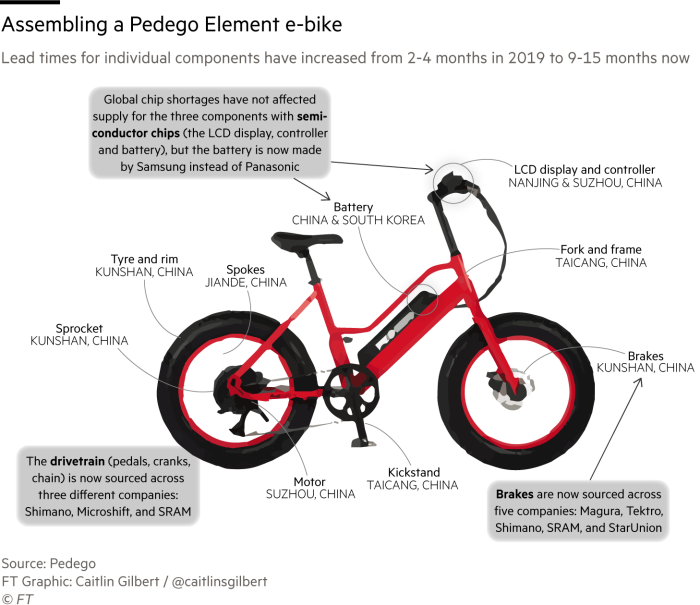

Like many other companies struggling to survive the supply chain crisis, Pedego had to work hard to keep its bicycles running because of its tight competition with Malaysian suppliers in the lithium-ion battery market. Close the factory Due to Covid-19, transportation costs have skyrocketed, containers have been trapped in port jams, and semiconductor shortages.

It uses a range of strategies to deal with it, from shipping batteries and bicycle racks separately to quickly changing suppliers when parts are short.

However, meeting the growing demand for electric bicycles in the United States remains a challenge. Earlier this month, a Pedego dealer on Main Street in Winnetka, Illinois, a wealthy suburb of Chicago, sold Elements in nine different colors. But the model runs out from July to late August, the owner Scottrade Liffe said.

“It’s so popular that there will be an accordion effect somewhere,” he added.

According to Jay Townley, co-founder of the consulting firm Human Powered Solutions, almost 100% of the US bicycle industry’s inventory is imported. Most of this is manual pedal power: historically, electric bicycles accounted for only 200,000 to 300,000 of the more than 17 million bicycles sold each year in the United States.

However, when the pandemic drives the bicycle boom, sales of electric bicycles have grown disproportionately. Tony said that some estimate that the number of electric bicycles sold in the United States last year was as high as 1 million.

Inventories were already low in the first quarter of 2020 as bicycle manufacturers reduced imports in response to tariffs imposed by former President Donald Trump.

Tonley said that when consumer demand surged in the second quarter, “then try [was] exist, . .. The pipeline started to fill up, but as the pipeline started to fill up, the supply chain began to creak.”

Pedego uses eight factories in Asia, of which five are in China, two are in Taiwan, and one is in Vietnam. DiCostanzo said the company ordered these factories to produce 37,000 bicycles of all models this year. When it later tried to increase this order by 10,000, it was unable to do so because the parts were not available.

Pedego manufactured Element’s first pre-production prototype in the spring of 2020, and then ordered 5,000. The bicycles were shipped from Shanghai in early July and arrived in California six weeks later.

One year later, the same journey can last twice as long. DiCostanzo said that it can even take up to two weeks to find a container in Shanghai Port. The company has begun to transport bicycles and batteries separately because when they are packaged together, they must be packed in containers of hazardous materials, which are more difficult to purchase.

Crossing the Pacific Ocean adds another two weeks, but it can take up to six weeks to cross the Port of Long Beach in Los Angeles. In one example, a batch of wicker bicycle baskets rotted in a container while waiting to be processed and shipped out of the port.

Then, the electric bike went to the warehouse in Orange County, and then drove for one to two weeks to the dealership.

In addition to delays, prices across the supply chain are also rising, with Pedego’s spending increasing from US$4,000 per container to US$23,000. At the same time, after freight operators increased freight rates, the cost of using a truck to transport a pallet with four bicycles from the company’s warehouse to the distributor rose from $8 to $18.

When Pedego was unable to purchase parts, it also made changes to Element, changing shifters from one brand to another, and changing its sprocket supplier. Due to the shortage of lithium-ion batteries, it also replaced its battery manufacturer from Panasonic to Samsung.

Tonley said that throughout the industry, during the pandemic and supply chain tightening, low-profile brands have flourished due to substitution.

For cheaper bikes—Element costs $1,895—replacement of components is easier. Pedego’s most expensive product, Elevate, at $5,495, will be out of stock throughout 2022 because manufacturers cannot obtain the necessary high-end parts from Japanese manufacturer Shimano.

“We have been begging them,” Dicostanzo said. “The more expensive the bicycle, the harder it is to buy the parts.”

Although Element contains chips in three components: an LCD display panel, a battery, and a controller that regulates the power of the machine, it has not been affected by the global shortage of semiconductors. However, Pedego has five new product lines. Because it is difficult to purchase the chips required for LCD displays, it now plans to launch these new product lines in June instead of January as originally planned.

Trade secrets

The British “Financial Times” revised “Trade Secrets”, which is its must-read daily newsletter on the changing face of international trade and globalization.

Register here Learn which countries, companies, and technologies are shaping the new global economy.

Last year, the company started allocating inventory and designated dealers to place orders on specific dates to avoid disappointment.

“I have 200 dealers,” DiCostanzo said. “I got a 155[bikes]… What should I do? We do our best to distribute them fairly. “

Pedego is now trying to stock up before the spring sales season. DiCostanzo said he has ordered 100,000 bicycles and hopes to get 60,000.

Earlier this month, one of Radliff’s Elements in Winnetka’s store had already put a “sold” label on the handlebar. The owner of this store is also an avid cyclist, providing free delivery service, and hopes to deliver it in person on Christmas Eve, playing the role of Santa Claus for customers.

But the new year looks uncertain. The bicycles ordered a few months ago are already on board and are heading to the United States. Tony said that if demand drops, excess inventory may force retailers into a price war.

If it stays strong—even though sales have fallen from its peak in 2020, but sales remain at historically high levels—frustrated shoppers may outnumber the available bicycles and electric bikes.

DiCostanzo said: “We have enough supply to take us until the end of January.” “After that, there is no guarantee because no one knows what the supply line will look like.”

[ad_2]

Source link