[ad_1]

This article is a live version of our trade secret newsletter.register here Send the newsletter directly to your inbox every Monday to Thursday

Hello from London, the arrival of Omicron means that on Christmas Eve, tequila has been replaced by a booster shot of the Covid-19 vaccine. The new variant of the novel coronavirus provides an interesting stress test to gauge how far the economy will move forward or resume behaviors that are conducive to the bumpy supply chain, such as strict border restrictions and the rapid growth of online shopping.

Our main job today is to pay attention to whether the maritime disruption has reached its peak. Although many people believe that the turbulence has reached its lowest point, we are not sure that the logistics industry will enter 2022.

We hope to hear from you.Send any ideas to [email protected] Or email me [email protected]

Shipping may be cheaper, but the delay still exists

There is now an atmosphere of optimism about the supply chain. The drop in freight rates has led several macroeconomists to put forward their recommendations for the 2022 outlook that the chaos we have witnessed in the past year and a half is beginning to clear.

Jan Hatzius, chief economist at Goldman Sachs, wrote in a report last week that “transportation costs and disruptions are beginning to normalize.” Bel Air Investment Advisors, a wealth management company, stated that “supply issues such as shipping prices have begun to normalize”.

In fact, freight rates in the spot market for containers from East Asia to the West Coast of the United States have fallen sharply. According to data providers Xeneta and Compass Financial, after reaching a peak of nearly US$9,000 per 40-foot equivalent unit in November, the cost of shipping goods from the world’s manufacturing center to the largest consumer market has fallen by more than 20% to 7,000 Sub-dollar technology.

There is further evidence that the number of waiting ships and containers in the Los Angeles and Long Beach port complex has decreased.

However, since mid-November, the situation in Los Angeles/Long Beach has become more difficult to assess, as new regulations require ships to stay several miles offshore before being allowed to approach. Although this makes the congestion seem to have eased, the ships are just waiting for further berths.

Even so, according to data from Sea/, a data platform owned by broker Clarksons, the number of calls at the busiest ports in the United States has declined in recent months, from 261 ships in September to 246 ships in October. And last month’s 216 ships.

However, many people in the industry are reluctant to say that disruption has reached its peak. They do not believe that the shipping business is normalizing like macroeconomists.

“We have not seen any significant improvement in the supply chain. Drewry analyst Simon Heaney said that the risk of further damage to the new version has increased.

He said that the recent drop in freight rates is due to seasonal declines in shipments that will not be able to catch up with Christmas, and airlines such as CMA CGM and Hapag-Lloyd have decided to freeze freight for those shipped on Christmas. last minute.

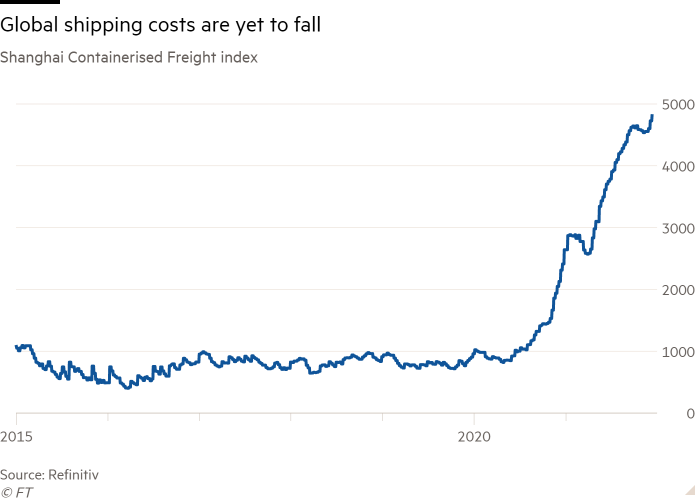

The decline in interest rates has also reversed globally. The Shanghai Container Freight Index hit a record high last week, almost five times the level at the beginning of 2020.

This is supported by Flexport’s marine timeliness index, which measures the time from when the goods leave the exporter to when they are collected at the port of destination. Both the Central European and Central American West Coast routes maintained or were close to historical highs of more than 100 days.

Lars Jensen, CEO of Vespucci Maritime, a consulting firm, said that the recent decrease in ship calls and container congestion in Los Angeles/Long Beach has eased, at the cost of making it less obvious. Ships lined up to wait longer to dock. The number of container ships waiting to berth on Monday reached a record 103.

“The core of the problem is still that you don’t have enough inland capacity to move containers,” he said.

As a trade secret Noticed earlier this weekEveryone, from purchasing managers to central bankers, is eager to have a clearer understanding of freight processes and bottlenecks through long and complex supply chains. Analysts have also been lamenting the lack of data tracking in the entire logistics network.

“Whether the inland areas have improved is quite opaque. There is no easy-to-read index on warehouse capacity or availability. There is no chassis number. To have a broad understanding on a regional and global scale, this is lacking,” Xi said. Ni said.

Xeneta’s Peter Sand said that among the many opaque factors in the supply chain, one of the most worrying issues is accurate data on the Chinese government’s policy in response to the coronavirus outbreak.

The large port of Ningbo was paralyzed for two weeks due to the pandemic in August. The recent series of cases have raised concerns about another closure, which will prevent shipping from returning to normal. “Lack of transparency… only adds to the mystery,” Sha added.

Some people say that having information clues without a complete tapestry can exacerbate the problem, leading to measures to relieve pressure in some areas, but at the cost of worsening other areas. Jensen said that the lack of a coherent picture not only fails to solve supply chain bottlenecks, it may even make the situation worse. The reason: a remedy for one problem may cause obstacles elsewhere.

For example, Hamburg changed its rules regarding how early trucks with export containers arrived at the port. The idea is to reduce box congestion in the docks, piers and yards. Jensen said that from the port’s perspective, this was a wise move, but it caused many trucks already on their way to the port to be shelved, thus removing truck capacity from the German supply chain.

There is no doubt that supply chain visibility startups that desperately need funding will claim that they have the tools to provide the useful data we all crave.

However, if supply chains prove one thing during the pandemic, it is that they are not technologically advanced enough that no one can calculate how low freight rates will fall. We can’t even call it the lowest point, let alone mitigate it.

Additional report by George Steer in London

Trade ties

Air freight price have Soar As exporters are eager to put their products on shelves and into warehouses before Christmas, prices hit new highs, which provides more evidence that Supply chain barriers Stay with us.

Before the weekend referendum, public opinion was Taiwan grace Restoration of the ban (Nikkei Index, USD) Yes U.S. pork importsThis move will have an impact on the relationship between Taipei and Washington.

Jude Webb has one Interesting reading how Dublin’s port is booming Reveals the shift in Irish trade Brexit. Francis Carregalado and Claire Jones

[ad_2]

Source link